Emerging Technologies in the Manufacturing Industry

The manufacturing industry has always been at the forefront of technological advancements. From the invention of the steam engine in the 18th century to the automation revolution in the 20th century, manufacturers have consistently embraced new technologies to streamline their processes and improve productivity. In recent years, several emerging technologies have gained significant attention in the manufacturing industry, offering new possibilities and opportunities for manufacturers.

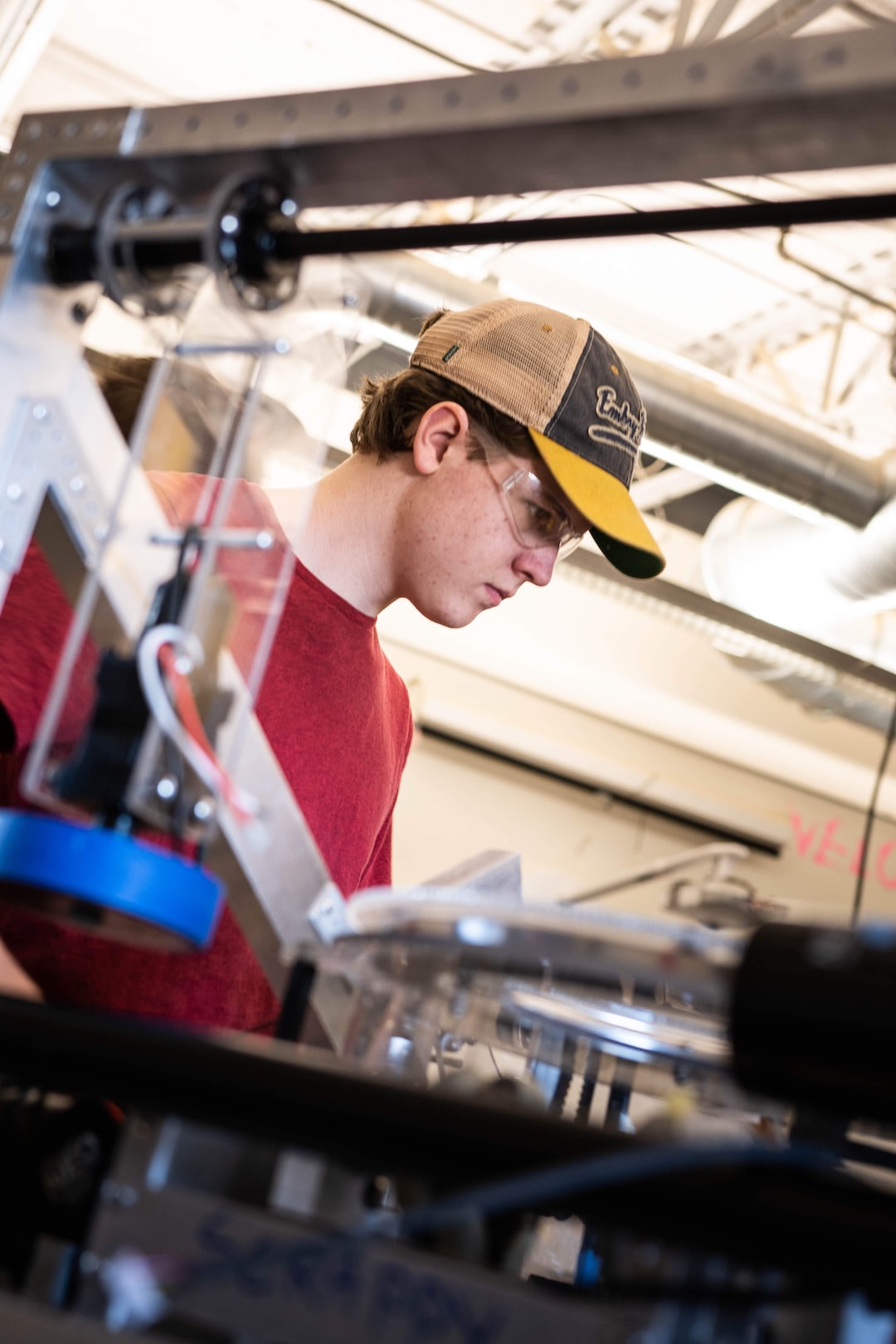

One of the most promising technologies that are revolutionizing the manufacturing process is additive manufacturing, more commonly known as 3D printing. 3D printing allows manufacturers to create complex shapes and structures that were previously impossible to produce. This technology enables enhanced customization, reduced material wastage, and faster prototyping. Industries such as aerospace, automotive, and healthcare have already started adopting 3D printing for manufacturing components, prosthetics, and even entire buildings. As the technology advances further and becomes more affordable, it is expected to have a profound impact on the manufacturing industry.

Another emerging technology that holds great potential for manufacturers is the Internet of Things (IoT). IoT refers to the connection of various physical devices to the internet, allowing them to communicate and share data. In the manufacturing industry, IoT can facilitate real-time monitoring of machines and equipment, predictive maintenance, and optimized supply chain management. By collecting and analyzing data from connected devices, manufacturers can identify inefficiencies, minimize downtime, and make data-driven decisions. IoT also enables the creation of smart factories, where machines and systems operate autonomously, resulting in increased productivity and efficiency.

Artificial intelligence (AI) is yet another emerging technology that is transforming the manufacturing industry. AI algorithms can analyze large volumes of data and identify patterns or anomalies that humans might overlook. This capability makes AI particularly useful in quality control, where it can detect defects or inconsistencies in manufactured products. AI-powered robots can also be utilized in tasks that are dangerous or repetitive for humans, improving worker safety and efficiency. By automating mundane or complex tasks, AI allows manufacturers to focus on value-added activities and enhances overall productivity.

Virtual reality (VR) and augmented reality (AR) are also making significant inroads in the manufacturing industry. VR provides immersive training environments where employees can practice complex procedures or interact with virtual prototypes. AR, on the other hand, overlays digital information onto the real world, providing real-time guidance to workers on the shop floor. These technologies enhance productivity by reducing errors, improving training effectiveness, and minimizing the time spent on troubleshooting. With the advent of affordable VR and AR devices, their adoption in manufacturing is expected to increase in the coming years.

Blockchain technology, primarily known for its association with cryptocurrencies, is also finding applications in the manufacturing industry. Blockchain provides a decentralized and secure platform for storing and managing transactions, making it ideal for supply chain management. It allows manufacturers to track and trace products from raw materials to end-users, ensuring transparency and reducing the risk of counterfeit or substandard products. Blockchain can also facilitate secure data sharing and collaboration between different stakeholders in the manufacturing process, improving efficiency and trust.

In conclusion, the manufacturing industry is witnessing a rapid influx of emerging technologies that are transforming the way products are made. From 3D printing and IoT to AI and VR/AR, these technologies are revolutionizing manufacturing processes, increasing efficiency, and driving innovation. Manufacturers who embrace these technologies stand to gain a competitive edge by reducing costs, improving product quality, and delivering superior customer experiences. As these technologies continue to evolve, it is crucial for manufacturers to stay abreast of the latest trends and explore opportunities to integrate them into their operations. The future of manufacturing is exciting, and those who harness the power of emerging technologies will undoubtedly thrive in this ever-evolving industry.