In manufacturing operations, keeping costs down is crucial for a company’s success. By reducing expenses, a company can improve its profit margins and stay competitive in the market. There are many strategies that companies can use to reduce costs in their manufacturing operations, ranging from investing in new technology to optimizing processes. In this blog post, we will explore some tips for reducing costs in your manufacturing operations.

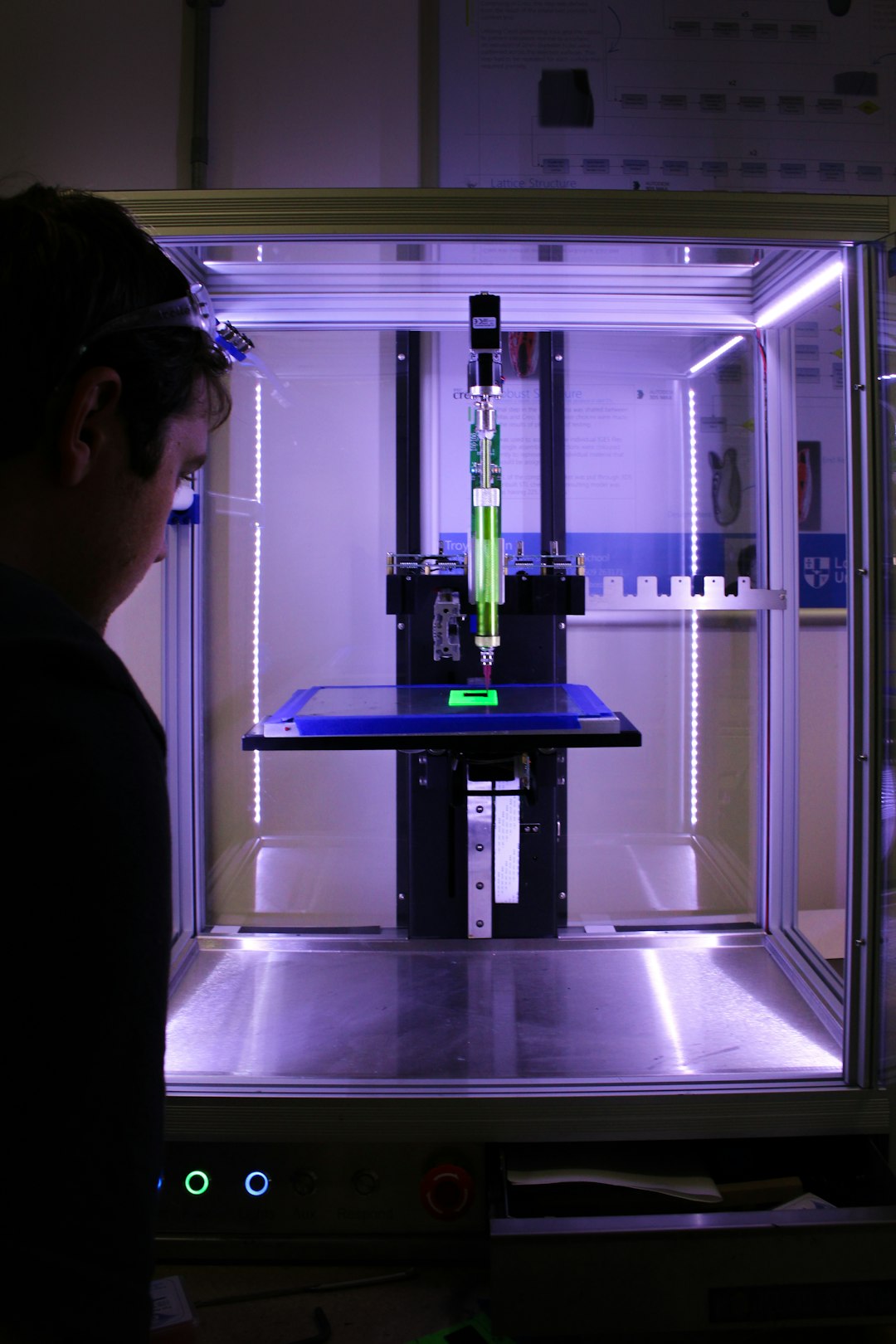

1. Invest in automation: One of the most effective ways to reduce costs in manufacturing operations is through automation. By utilizing robotics and other automation technologies, companies can increase efficiency, reduce labor costs, and improve accuracy. Automation can also help to standardize processes and reduce waste, leading to cost savings in the long run.

2. Optimize your supply chain: Another way to reduce costs in manufacturing operations is by optimizing your supply chain. By working closely with suppliers, you can negotiate better prices, reduce lead times, and improve overall efficiency. It’s important to regularly review and assess your supply chain to identify potential areas for cost savings.

3. Implement lean manufacturing principles: Lean manufacturing is a methodology that focuses on optimizing processes and eliminating waste. By implementing lean principles in your manufacturing operations, you can reduce costs, improve quality, and increase productivity. Some key principles of lean manufacturing include just-in-time production, continuous improvement, and value stream mapping.

4. Streamline production processes: By streamlining your production processes, you can reduce costs and improve efficiency. Look for areas where you can eliminate bottlenecks, reduce setup times, and improve workflow. Implementing a production schedule and using visual management tools can help to streamline processes and reduce costs.

5. Reduce energy consumption: Energy costs can be a significant expense in manufacturing operations. By implementing energy-saving measures, such as switching to LED lighting, optimizing heating and cooling systems, and investing in energy-efficient equipment, you can reduce energy costs and improve your bottom line.

6. Implement predictive maintenance: Equipment downtime can be costly for manufacturing operations. By implementing a predictive maintenance program, you can anticipate when equipment will need maintenance and prevent costly breakdowns. Regular maintenance can also help to extend the lifespan of equipment and reduce overall maintenance costs.

7. Evaluate outsourcing options: Sometimes it may be more cost-effective to outsource certain aspects of your manufacturing operations, such as assembly or packaging. By evaluating outsourcing options, you can identify ways to reduce costs and improve efficiency. Just be sure to carefully vet potential outsourcing partners to ensure they meet your quality standards.

8. Invest in employee training: Well-trained employees are more productive and can help to reduce costs in manufacturing operations. By investing in employee training programs, you can improve efficiency, reduce errors, and increase overall quality. Training employees on new technologies and processes can also help to streamline operations and reduce costs.

9. Monitor and analyze data: In order to reduce costs in manufacturing operations, it’s important to monitor and analyze data to identify areas for improvement. By tracking key performance indicators (KPIs) and analyzing data, you can identify trends, optimize processes, and make informed decisions to reduce costs.

10. Continuously look for ways to improve: Finally, reducing costs in manufacturing operations is an ongoing process. It’s important to continuously look for ways to improve processes, implement new technologies, and identify cost-saving opportunities. By fostering a culture of continuous improvement, you can stay competitive in the market and reduce costs in your manufacturing operations.

In conclusion, reducing costs in manufacturing operations is essential for a company’s success. By investing in automation, optimizing your supply chain, implementing lean principles, and streamlining production processes, you can reduce costs and improve efficiency. By following these tips and continuously looking for ways to improve, you can stay competitive in the market and achieve long-term success in your manufacturing operations.